Capabilities

Clear-pak Australia uses an extensive range of high quality box making grade materials to fabricate its clear plastic packaging products. Raw materials are sourced from the world’s best suppliers to ensure a top quality product. Clarity is consistent, material has high impact strength and is scratch resistant. This means that our clear boxes and other packaging items are of the highest quality and can be tailored to suit your product’s needs. We offer a number of different packaging solutions, so have a variety of manufacturing processes which allow a range of custom made products all produced in one place.

Runs of all sizes

We’re geared to do small, medium and large runs ranging from simple to very complex projects. We can therefore offer relatively low tooling costs, even on small runs (no tooling on lid/base and cylinder products).

Quoting & Sampling

Our simple quoting system plus a rapid sampling service helps you to make the right choice – contact us to find out more.

If we can’t produce all elements on site, we have an extensive network of reliable suppliers who can.

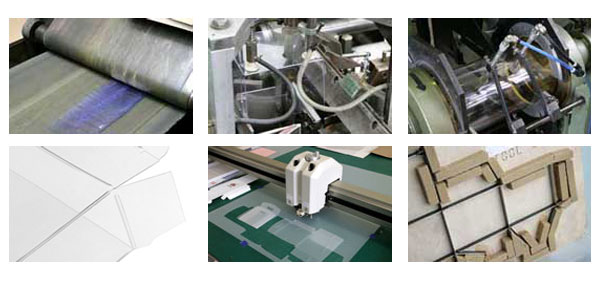

Processes

Using the latest in production technology, our processes ensure a quality product produced on time and on budget:

- Box making machines

- Die cutting

- Automated folder gluer

- Automated cylinder machines and beading

- Soft crease machines

- Ultrasonic welding equipment

- Sheeting

- Vacuum forming

- Design and sampling

Materials

We make it a priority to source the best quality materials, to ensure production of a quality product.

- APET, RPET, GAG, PETG – RPET contains 20% to100% recycled PET

- PVC – clear, coloured or frosted

- Polypropylene

- Plant based materials (PLA) – vacuum form only

- Cardboard – various grades and colours

- All material is 100% recyclable if printed or embossed with the appropriate recycle logo

- All materials and processes are approved for direct contact with food